Measurement Techniques and Testings

The company Reinhard Tweer GmbH is certified acc. to 9001:2015.

The following processes are possible for the analyses:

Full automatically spectrographic analysis

To insure the material quality each melting charge is analysed with an emission spectrometer for several times. Within short time the quantification of all essential iron companion incl. the micronutrients and gases takes place. All information are transfered in the data processing system automatically.

Determination of the mechanical characteristics

For determination the mechanical characteristics e.g. tensile strenght, yield strenght, elongation and impact value we have reliable equipment in the material testing.

The production of the samples is made at Reinhard Tweer GmbH directly.

The testing of low temperature notched specimen is possible up to -80°C.

The testing of the equipment and also the calibration is made by an external accredited testing institute yearly.

Measuring room

Two index arms with variable 360° links reach each measuring point at the components for determination of the metrical requirements. Also contact-free measuring by laserscan and the consequential reverse engineering is possible without any problems.

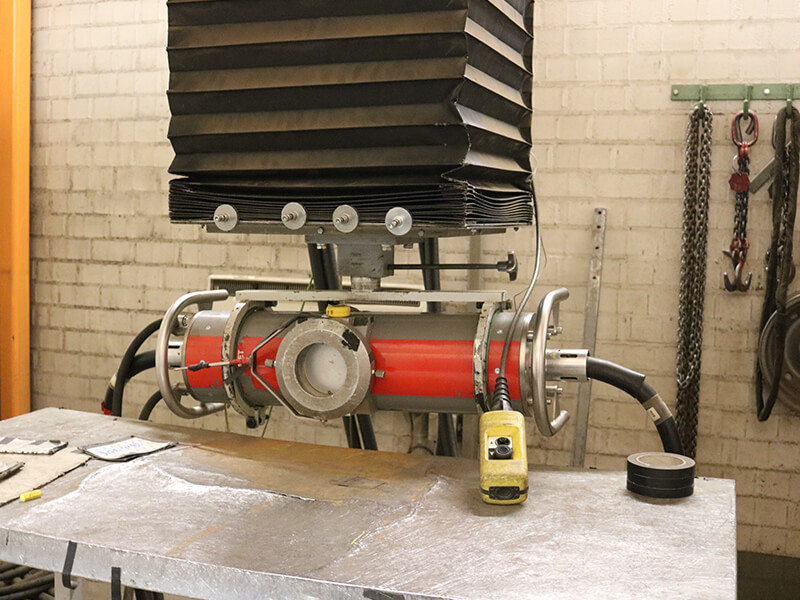

Radiographic examination

The 450 kV electron-beam tube penetrated by radiation the cast parts within short time. Fixed in a “3-axis-manipulator” the angles for testing will be positioned exactly also at bulky parts. The fully automatic processing brings this discipline of testing for reliable volume mistake identification down to a round figure.

Ultrasonic examination

In order to perform the requirements to identificate volume mistakes we have amongst others several modern ultrasonic test instruments. A wide choice of different search units protects the handling of all test functions.

Crack test

Unknowable surface defects – which are not visible with the naked eye – are detected reliable by magnetic powder crack testing at several working places. Big magnetic field generators and variable applicable pole contactors are protecting the test results also by complicated part geometry.

Certificates

BVC | DIN EN ISO 9001:2015

SLV | Ü mark

DVS | Weldability according to DIN EN 15085-2

DVS | Weldability according to DIN EN ISO 3834-2

TÜV | European Pressure Equipment Directive /TRD100/ADW0

TÜV | DIN EN ISO 50001:2018

BV | Shipbuilding Approval ESN/3350/1.A.O.

DB | Production Qualification Steel Casting/Sphere Cast Iron

DB | Ductile iron superstructure qualification

DB | Quality Capability Classification Q1

LRS | Factory Approval Cast Steel

LRS | Factory Approval Ductile Iron

DNV | Factory Approval Ductile Iron

DNV | Factory Approval Cast Steel